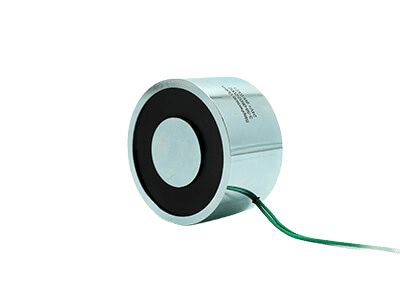

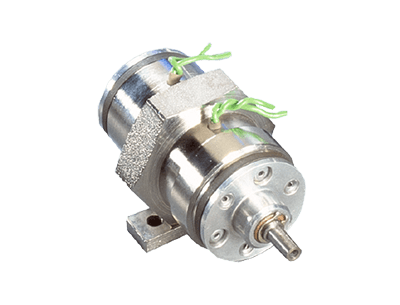

Toothed brake

High torque, power on toothed brake preventing slip in static and low speed applications.

Enquire NowKey features

- High torque

- Compact size

- No slip

- Zero drag torque

- Optional number of teeth

- Power on engagement

- Optional voltages

Product description

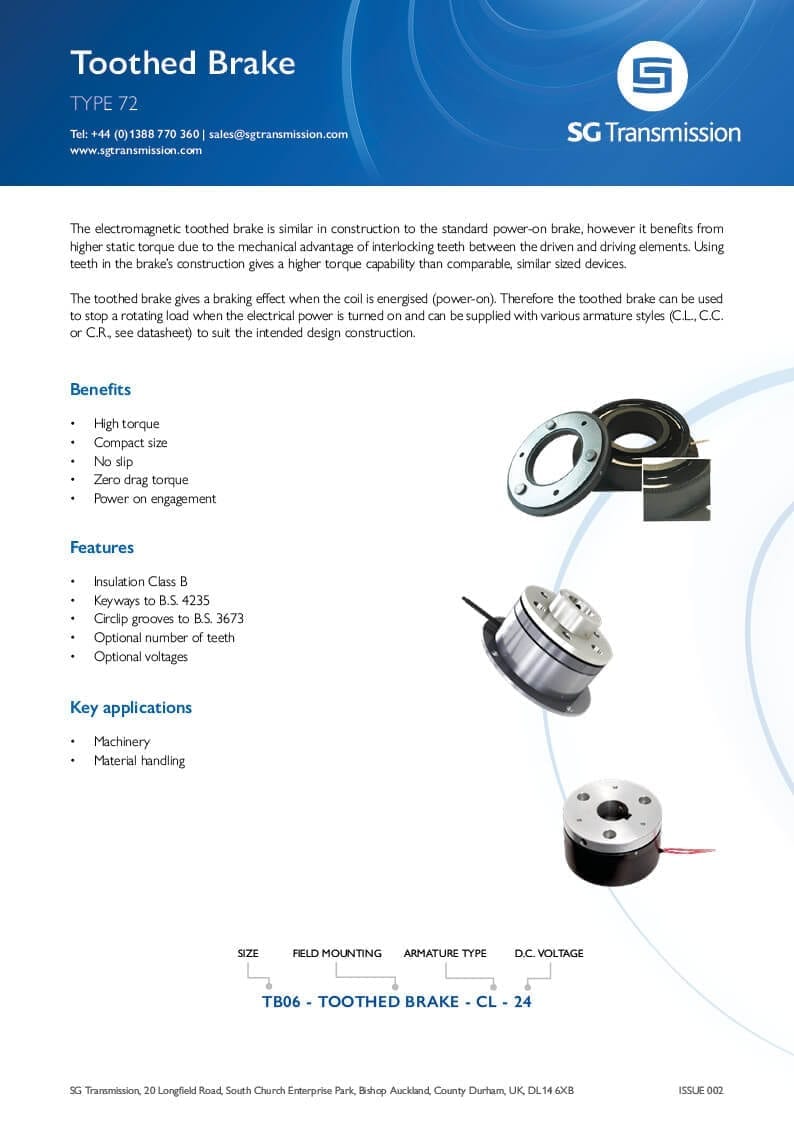

The electromagnetic toothed brake is similar in construction to the standard power-on brake, however it benefits from higher static torque due to the mechanical advantage of interlocking teeth between the driven and driving elements. Using teeth in the brake’s construction gives a higher torque capability than comparable, similar sized devices.

The toothed brake gives a braking effect when the coil is energised (power-on). Therefore the toothed brake can be used to stop a rotating load when the electrical power is turned on and can be supplied with various armature styles (C.L., C.C. or C.R., see datasheet) to suit the intended design construction.

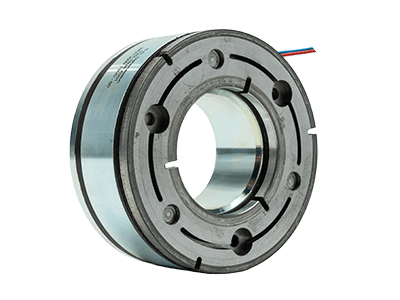

The toothed geometry can be designed to enhance the torque achieved and can also be modified to give a particular number of indexing positions i.e. one per revolution, two per revolution and so on. This means the toothed brake can be used where there is a requirement to synchronise the rotating elements.

The toothed brake is generally used for static or low speed engagement in applications such as access control systems, indexing systems in machine tools and labelling machines.

When the toothed brake is engaged, there is ‘no slip’ from the brake as the torque is driven by the teeth. As slippage is non-existent, braking is more precise and predictable. During manufacture, the brake’s teeth can be hardened by heat treatment to minimise the wear and tooth deformation under load, which increases the life of the brake.

The toothed brake can be used in a wide range of environmental conditions as due to the teeth technology, ambient temperatures will not affect the brake’s torque. This brake is generally used in dry operations.

All of our electromagnetic brake designs can be customised to suit particular requirements. We can design toothed brakes with various torques dependent on the application and envelope size available.

Key features

- High torque

- Compact size

- No slip

- Zero drag torque

- Optional number of teeth

- Power on engagement

- Optional voltages

Product description

The electromagnetic toothed brake is similar in construction to the standard power-on brake, however it benefits from higher static torque due to the mechanical advantage of interlocking teeth between the driven and driving elements. Using teeth in the brake’s construction gives a higher torque capability than comparable, similar sized devices.

The toothed brake gives a braking effect when the coil is energised (power-on). Therefore the toothed brake can be used to stop a rotating load when the electrical power is turned on and can be supplied with various armature styles (C.L., C.C. or C.R., see datasheet) to suit the intended design construction.

The toothed geometry can be designed to enhance the torque achieved and can also be modified to give a particular number of indexing positions i.e. one per revolution, two per revolution and so on. This means the toothed brake can be used where there is a requirement to synchronise the rotating elements.

The toothed brake is generally used for static or low speed engagement in applications such as access control systems, indexing systems in machine tools and labelling machines.

When the toothed brake is engaged, there is ‘no slip’ from the brake as the torque is driven by the teeth. As slippage is non-existent, braking is more precise and predictable. During manufacture, the brake’s teeth can be hardened by heat treatment to minimise the wear and tooth deformation under load, which increases the life of the brake.

The toothed brake can be used in a wide range of environmental conditions as due to the teeth technology, ambient temperatures will not affect the brake’s torque. This brake is generally used in dry operations.

All of our electromagnetic brake designs can be customised to suit particular requirements. We can design toothed brakes with various torques dependent on the application and envelope size available.

To download the technical drawings for this product fill in your details below and we will send you a link to the files.

"*" indicates required fields

Toothed brake technical drawing

Please enquire for full technical specification

Toothed brake datasheetSee related downloads for full datasheet

| Size | Torque TS (Nm) | Max P20 (W) | Outside Ø | Brake field length | CC armature depth | Max Bore Diameter | E4 | Airgap |

|---|---|---|---|---|---|---|---|---|

| TB06 | 21 | 15 | 63 | 20 | 15 | 35 | 35 | 0.3 |