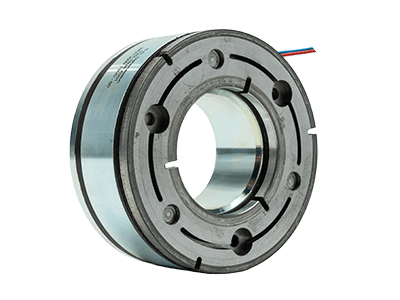

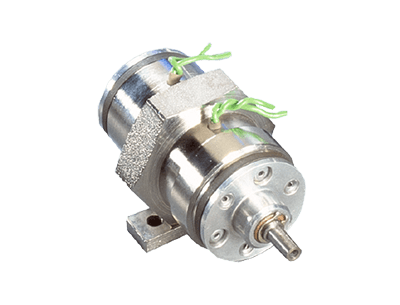

Spring applied power off brake

Fail-safe, spring applied power off brakes for use in demanding applications. Designed with power-off brake engagement, engaging when electrical power supply is removed.

Enquire NowKey features

- Fail-safe (Spring Applied)

- Power off brake engagement/electrically released

- High braking torque

- High operating speeds (dependent on size)

- Precision holding

- Low moment of inertia

- Horizontal and vertical mounting

- Splined hub/friction disc connection

- Water resistant versions available

- Optional voltages

Product description

The electromagnetic spring applied power off brake (sometimes known as a safety brake or fail-safe brake) is designed so that when the electrical power supply is removed, the brake engages (power-off brake engagement). The spring applied brake can be designed to be used as a holding brake (parking), or dynamically when an emergency stop function is required (E-stop).

Our spring applied power off brakes are robust and reliable, generally incorporating multiple internal compression springs. The multiple springs provide an added safety feature, ensuring that the brake would still function should one spring fail prematurely. When power is cut the coil’s magnetic field decays, the springs force an axially moving armature plate forwards to engage and lock the rotating friction disc. The electromagnetic spring applied brake is ideal for integration into servomotors and can be mounted externally or integrated into the motor housing.

Friction options

The electromagnetic spring applied brake is one of our most versatile brakes with a torque range of 0.05Nm to 300Nm. The non-asbestos lining construction of the rotating friction element is available in three different types (depending upon the application and torque required):

1. Mainly static applications – single piece friction disc assembly, with drive interface direct into friction discs

2. Mainly semi-dynamic applications – aluminum carriers with double bonded friction discs for increased shear strength and shock loading

3. Higher strength applications – steel carriers of hardened steel with double bonded friction discs, for more demanding and dynamic applicationsDepending on the acceptable level of backlash, some spring applied power off brakes have the option to have either a spline or hexagonal drive ensuring minimal circumferential backlash.

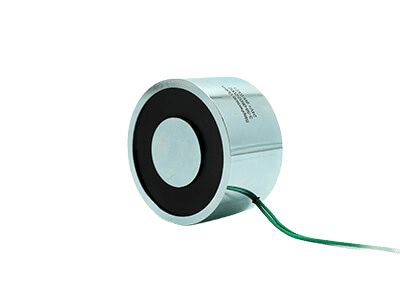

Air gap

During its manufacture, the air gap is pre-set on the spring applied brake for ease of installation. Where longer term `in-situ` air gap resetting is required, this can be achieved with adjustable spacers, without needing to totally remove the brake from the motor.

Override release

The spring applied brake has a hand release option to manually override the brake without power. This is suited to applications such as fork lift truck machinery, wheelchairs and actuation and valve systems.

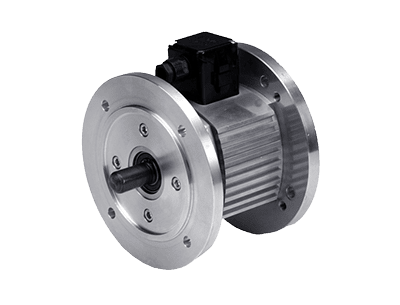

Mounting options

The spring applied power off brake can be face mounted or flange mounted in any orientation and due to its reliability, is suited to safety critical applications in the material handling, military and medical sectors. They are often used in automation and robotic applications as well as packaging machines, storage systems and in renewable energy.

Temperature tolerance

As the spring applied brake does not contain permanent magnetic material, it is more tolerant of high temperatures than the permanent magnet brake. Its temperature range is between – 15°C to 120°C. An ‘IP’ water (or “Ingress Protection”) resistant design may also be available for installation into moist environments.

Rubber dust sealing rings may be incorporated to prevent ingress of foreign matter. Drive hubs can be supplied with brakes, complete with bore and keyways to suit the specific application.

Key features

- Fail-safe (Spring Applied)

- Power off brake engagement/electrically released

- High braking torque

- High operating speeds (dependent on size)

- Precision holding

- Low moment of inertia

- Horizontal and vertical mounting

- Splined hub/friction disc connection

- Water resistant versions available

- Optional voltages

Product description

The electromagnetic spring applied power off brake (sometimes known as a safety brake or fail-safe brake) is designed so that when the electrical power supply is removed, the brake engages (power-off brake engagement). The spring applied brake can be designed to be used as a holding brake (parking), or dynamically when an emergency stop function is required (E-stop).

Our spring applied power off brakes are robust and reliable, generally incorporating multiple internal compression springs. The multiple springs provide an added safety feature, ensuring that the brake would still function should one spring fail prematurely. When power is cut the coil’s magnetic field decays, the springs force an axially moving armature plate forwards to engage and lock the rotating friction disc. The electromagnetic spring applied brake is ideal for integration into servomotors and can be mounted externally or integrated into the motor housing.

Friction options

The electromagnetic spring applied brake is one of our most versatile brakes with a torque range of 0.05Nm to 300Nm. The non-asbestos lining construction of the rotating friction element is available in three different types (depending upon the application and torque required):

1. Mainly static applications – single piece friction disc assembly, with drive interface direct into friction discs

2. Mainly semi-dynamic applications – aluminum carriers with double bonded friction discs for increased shear strength and shock loading

3. Higher strength applications – steel carriers of hardened steel with double bonded friction discs, for more demanding and dynamic applicationsDepending on the acceptable level of backlash, some spring applied power off brakes have the option to have either a spline or hexagonal drive ensuring minimal circumferential backlash.

Air gap

During its manufacture, the air gap is pre-set on the spring applied brake for ease of installation. Where longer term `in-situ` air gap resetting is required, this can be achieved with adjustable spacers, without needing to totally remove the brake from the motor.

Override release

The spring applied brake has a hand release option to manually override the brake without power. This is suited to applications such as fork lift truck machinery, wheelchairs and actuation and valve systems.

Mounting options

The spring applied power off brake can be face mounted or flange mounted in any orientation and due to its reliability, is suited to safety critical applications in the material handling, military and medical sectors. They are often used in automation and robotic applications as well as packaging machines, storage systems and in renewable energy.

Temperature tolerance

As the spring applied brake does not contain permanent magnetic material, it is more tolerant of high temperatures than the permanent magnet brake. Its temperature range is between – 15°C to 120°C. An ‘IP’ water (or “Ingress Protection”) resistant design may also be available for installation into moist environments.

Rubber dust sealing rings may be incorporated to prevent ingress of foreign matter. Drive hubs can be supplied with brakes, complete with bore and keyways to suit the specific application.

To download the technical drawings for this product fill in your details below and we will send you a link to the files.

"*" indicates required fields

Spring applied power off brake technical drawing

See related downloads for full datasheet

Download drawingsSee related downloads for full datasheet

| Unit ref | Static Torque (Nm) | A - Diameter (mm) | L - Length (mm) | Maximum Bore | Power (Watts) | Voltage (V) |

|---|---|---|---|---|---|---|

| SA-35 | 0.15 | 35 | 27.0 | 6.0 | 5.0 | 12 or 24 |

| SA-40 | 0.4 | 40 | 30.5 | 8.0 | 5.3 | 12 or 24 |

| SA-42 | 0.4 | 42 | 32.0 | 8.0 | 5.0 | 12 or 24 |

| SA-55 | 2.5 | 55 | 32.0 | 8.0 | 12.0 | 12 or 24 |

| SA-60 | 4.0 | 60 | 32.0 | 8.0 | 12.0 | 12 or 24 |

| SA-70 | 7.0 | 70 | 34.1 | 15.0 | 15.0 | 12 or 24 |

| SA70-1 | 10.0 | 70 | 46.5 | 15.0 | 17.3 | 12 or 24 |

| SA-77 | 6.0 | 77 | 39.9 | 20/25* | 16.0 | 12 or 24 |

| SA77-1 | 12.0 | 77 | 39.9 | 20/25* | 20.0 | 12 or 24 |

| SA-90 | 20.0 | 90 | 43.9 | 20/25* | 20.0 | 12 or 24 |