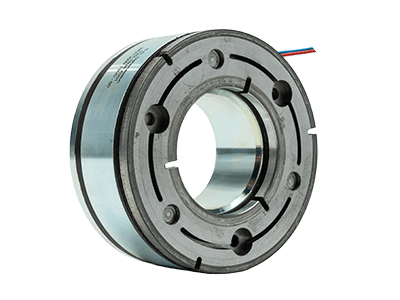

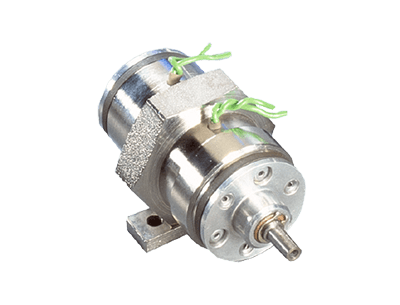

Power on flange mounted clutch

A backlash free, durable option for controlling motion in high torque applications.

Enquire NowKey features

- Backlash-free

- Long life expectancy

- Durable construction

- Choice of drive hubs to suit application

- Customised keyway and bore options

- Voltage options

- Ease of fitting

- Optional armature hubs

Product description

The power on flange mounted clutch (also known as electromagnetic power on clutch) transmits drive when the coil is energised. The flange mounted clutch can be engaged statically and dynamically and is available in various sizes, torques and multipole high torque versions.

Used to transmit rotary motion when the electrical power is turned on, the flange mounted clutch and can be supplied with various armature styles (C.L., C.C. or C.E.) to suit the intended design layout. These consist of an armature plate and return spring (C.L. form), an integral hub with a bore and key way ( C.C. form) or, with internal bearings (C.E. form).

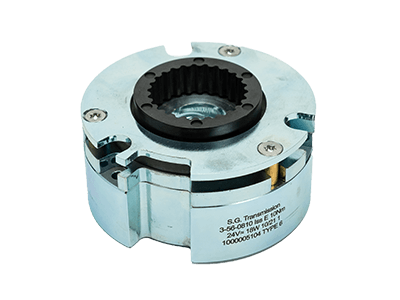

The high torque variant (multi-pole) gives a higher static torque within a smaller envelope size reducing overall weight, wear and the number of start/stops required by the primary motor therefore improving motor life.

Due to its solid construction, the flange mounted clutch is considered as ‘torsionally rigid’ and therefore backlash free, minimising unwanted movement under load. Due to this, flange mounted clutches are typically used in the automation, military and medical industries as well as food processing, collating and packaging machines.

Our engineers can work with you to develop a design suited to your requirements, altering specifications such as envelope size, operating temperature and lead or termination options to suit your request.

Key features

- Backlash-free

- Long life expectancy

- Durable construction

- Choice of drive hubs to suit application

- Customised keyway and bore options

- Voltage options

- Ease of fitting

- Optional armature hubs

Product description

The power on flange mounted clutch (also known as electromagnetic power on clutch) transmits drive when the coil is energised. The flange mounted clutch can be engaged statically and dynamically and is available in various sizes, torques and multipole high torque versions.

Used to transmit rotary motion when the electrical power is turned on, the flange mounted clutch and can be supplied with various armature styles (C.L., C.C. or C.E.) to suit the intended design layout. These consist of an armature plate and return spring (C.L. form), an integral hub with a bore and key way ( C.C. form) or, with internal bearings (C.E. form).

The high torque variant (multi-pole) gives a higher static torque within a smaller envelope size reducing overall weight, wear and the number of start/stops required by the primary motor therefore improving motor life.

Due to its solid construction, the flange mounted clutch is considered as ‘torsionally rigid’ and therefore backlash free, minimising unwanted movement under load. Due to this, flange mounted clutches are typically used in the automation, military and medical industries as well as food processing, collating and packaging machines.

Our engineers can work with you to develop a design suited to your requirements, altering specifications such as envelope size, operating temperature and lead or termination options to suit your request.

To download the technical drawings for this product fill in your details below and we will send you a link to the files.

"*" indicates required fields

Power on flange mounted clutch technical drawing

See related downloads for full datasheet

Download drawingsSee related downloads for full datasheet

| Size | Torque TS (Nm) | Max P20 (W) | A1 H9 | A2 | A3 | B | C1 | C4 | C5 | Max E1 H7 | Max E2 H7 | E3 | E4 H8 | E5 | E6 K6 | G | H1 | K | N1 | N2 | N3 | R1 | S1 | S3 | T | U1 x4 | U2 | U6 | U7 | V | W1 | W2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 00 | 0.30 | 5 | 38 | 28.6 | 28 | 18.6 | 12.5 | 7 | - | 6.5 | 6.5 | - | 11 | 10 | - | 0.1 | 0.5 | 5 | 33.3 | 19.5 | - | 15.5 | 9.7 | - | 1.5 | 3.2 | 2x2.6 | - | M3 | 1 | 4.5 | - |

| 01 | 0.60 | 6 | 38 | 30 | 31 | 18.5 | 13.6 | 10 | - | 6.5 | 6.5 | - | 11.5 | 12 | - | 0.1 | 0.5 | 5 | 33.3 | 19.5 | - | 16.5 | 12.8 | - | 1.5 | 2.6 | 2x2.6 | - | M3 | 1 | 8 | - |

| 02 | 0.75 | 6 | 45 | 32 | 34 | 25 | 20.2 | 10 | - | 6.5 | 6.5 | - | 13 | 12 | - | 0.1 | 2 | 5 | 38 | 23 | - | 22.2 | 12.8 | - | 2 | 3.5 | 3x2.6 | - | M3 | 1.5 | 8 | - |

| 03 | 1.20 | 8 | 54 | 40 | 43 | 28.5 | 23.4 | 12 | - | 10 | 10 | - | 19 | 17 | - | 0.15 | 2.2 | 6.1 | 47 | 30 | - | 25.6 | 15.3 | - | 2 | 3.5 | 3x3.1 | - | M3 | 1.5 | 9.5 | - |

| 04 | 1.60 | 10 | 62 | 42 | 44 | 28.8 | 19 | 12 | - | 10 | 10 | - | 19 | 17 | - | 0.15 | 2.2 | 6.1 | 54 | 19 | - | 25.4 | 15.3 | - | 2 | 5 | 2x3.1 | - | M3 | 1.5 | 9.5 | - |

| 05 | 3 | 10 | 65 | 50 | 54 | 31.8 | 26.1 | 12 | 12 | 15 | 15 | 7 | 26 | 24 | 30 | 0.2 | 2 | 6.1 | 58 | 38 | 24 | 28.1 | 15.3 | 18 | 2 | 3.5 | 3x3.1 | 3xM3 | M4 | 1.5 | 9.5 | 12 |

| 06 | 8 | 15 | 80 | 63 | 66.5 | 28 | 22 | 15 | 20 | 17 | 17 | 12 | 35 | 27 | 38 | 0.2 | 2 | 6.1 | 72 | 46 | 33 | 24 | 19 | 27 | 2 | 4.5 | 3x3.1 | 3xM4 | M5 | 1.5 | 11.5 | 20 |

| 07 | 8 | 15 | 89 | 63 | 68 | 36 | 22.5 | 15 | 20 | 15 | 17 | 12 | 27 | 27 | 38 | 0.2 | 9.5 | 6.1 | 79.5 | 60 | 33 | 32 | 17 | 27 | 2 | 5 | 3x3.1 | 3xM4 | M5 | 1.5 | 11.5 | 20 |

| 08 | 16 | 18 | 100 | 80 | 85 | 31 | 24 | 20 | 23.5 | 22 | 20 | 15 | 42 | 32 | 45 | 0.2 | 2.5 | 8 | 90 | 60 | 37 | 26.5 | 24.7 | 34 | 2.5 | 5.5 | 3x4.1 | 3xM4 | M5 | 2 | 16 | 25 |

| 10 | 32 | 31 | 125 | 100 | 107 | 36 | 27 | 25 | 32 | 30 | 30 | 20 | 52 | 42 | 55 | 0.2 | 3 | 9 | 112 | 76 | 47 | 30 | 30 | 41 | 3 | 6.5 | 3x5.1 | 4xM4 | M6 | 2 | 19 | 30 |

| 11 | 32 | 25 | 143 | 105 | 107 | 42 | 33 | 25 | 32 | 25 | 30 | 20 | 47.6 | 42 | 55 | 0.2 | 4.7 | 9 | 127 | 76 | 47 | 38 | 30 | 41 | 3 | 7.5 | 3x5.1 | 4xM4 | M6 | 2 | 20 | 30 |

| 12 | 65 | 32 | 150 | 125 | 133 | 41 | 30 | 30 | 42 | 40 | 35 | 25 | 62 | 49 | 64 | 0.3 | 3.5 | 10 | 137 | 95 | 52 | 33.5 | 37.2 | 53.5 | 3.5 | 6.5 | 3x6.1 | 4xM4 | M6 | 2.5 | 24 | 40 |

| 16 | 120 | 45 | 190 | 160 | 170 | 47 | 38 | 38 | 54 | 50 | 40 | 30 | 80 | 65 | 75 | 0.3 | 3.5 | 13 | 175 | 120 | 62 | 37.5 | 48 | 66 | 4 | 9 | 3x8.2 | 6xM5 | M8 | 9 | 30 | 50 |

| 20 | 240 | 65 | 230 | 200 | 213 | 54 | 40 | 48 | 67 | 65 | 60 | 40 | 100 | 92 | 90 | 0.5 | 4 | 16 | 215 | 158 | 75 | 44 | 59 | 80.9 | 5 | 9 | 3x10.2 | 4xM6 | M8 | 11 | 39 | 60 |