Permanent magnetic hysteresis

Designed for continuous slip or overload protection.

Enquire NowKey features

- Constant torque

- Simple adjustment

- Long life

- No electrical power required

Product description

Permanent magnetic hysteresis clutches and brakes have been designed to maintain high performance in continuous slip applications through maximum and continuous heat dissipation.

The use of high wear resistant particles assures long operational life in high cycle applications.

Since torque is transmitted via a hysteresis field, there is minimal difference between the static and the dynamic torque. These units are unaffected by friction and wear, therefore torque is substantially more accurate and repeatable than friction tensioners.

A consistent torque is maintained regardless of allowable slip speed due to the hysteresis principle.

Long life

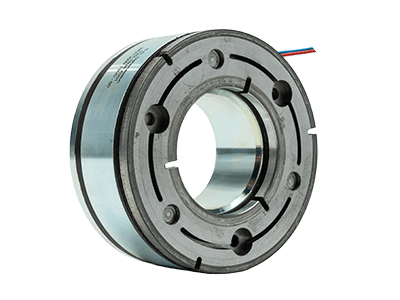

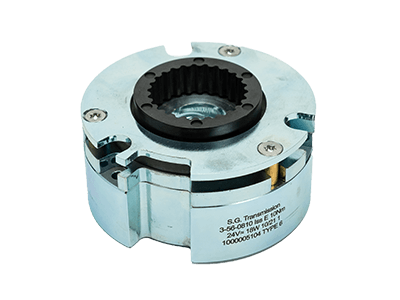

There is virtually no wear because permanent magnets and hysteresis disks transmit the torque by magnetic flux without physical contact.

Simple installation

Units are provided bearing mounted and pre-assembled.

No contamination

Units are sealed which protect against contamination from equipment. There are also no wear particles from operation to contaminate equipment

No electrical power needed

The PHR Series clutches and brakes operate on a permanent magnet principle. External electrical connection is not required, therefore units function independently from power fluctuation.

Constant torque (adjustable)

Units can deliver set torque regardless of speed range. Each unit’s torque settings may be manually adjusted over a wide range providing great flexibility.

Vertical and horizontal operation possible

Units can be mounted in any axis and can be run either clockwise or counter-clockwise without affecting performance.

Key features

- Constant torque

- Simple adjustment

- Long life

- No electrical power required

Product description

Permanent magnetic hysteresis clutches and brakes have been designed to maintain high performance in continuous slip applications through maximum and continuous heat dissipation.

The use of high wear resistant particles assures long operational life in high cycle applications.

Since torque is transmitted via a hysteresis field, there is minimal difference between the static and the dynamic torque. These units are unaffected by friction and wear, therefore torque is substantially more accurate and repeatable than friction tensioners.

A consistent torque is maintained regardless of allowable slip speed due to the hysteresis principle.

Long life

There is virtually no wear because permanent magnets and hysteresis disks transmit the torque by magnetic flux without physical contact.

Simple installation

Units are provided bearing mounted and pre-assembled.

No contamination

Units are sealed which protect against contamination from equipment. There are also no wear particles from operation to contaminate equipment

No electrical power needed

The PHR Series clutches and brakes operate on a permanent magnet principle. External electrical connection is not required, therefore units function independently from power fluctuation.

Constant torque (adjustable)

Units can deliver set torque regardless of speed range. Each unit’s torque settings may be manually adjusted over a wide range providing great flexibility.

Vertical and horizontal operation possible

Units can be mounted in any axis and can be run either clockwise or counter-clockwise without affecting performance.

To download the technical drawings for this product fill in your details below and we will send you a link to the files.

"*" indicates required fields