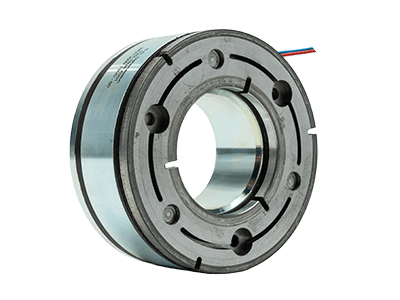

Clutch brake

Backlash free clutch brakes for an accurate and controlled “stop and start” action.

Enquire NowKey features

- Simple fit to IEC motors and gearboxes

- Easy installation

- Zero-backlash

- Good heat dissipation

- High cycle times

- Voltage options

Product description

SG Transmission clutch brake modules are used whenever the prime mover is required to run continuously, and the output of the driving device requires a controlled “stop and start” action. This allows an electric motor to run while controlling its output via a clutch brake module. This will reduce the power consumption of the system considerably.

These modules are precision engineered with positive clutch and brake action with no backlash. They can be controlled by relatively simple solid state electronics to give accurate stopping and starting with frequencies over 300 cycles per minute.

Easy installation

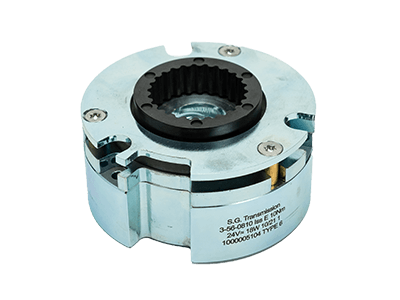

The clutch and brake are ready assembled in a neat package which can be foot mounted or fitted to a standard IEC motor and reducer flanges.

Robust construction

Type 55 modules are completely enclosed and use deep groove ball bearings on the input and output. They can be mounted in any position, vertically or horizontally.

Zero backlash

The clutch and brake use a common driven armature, and therefore backlash during torque transmission and braking is eliminated.

Safety

Clutch and brake linings are hard wearing and do not contain asbestos.

Low wear rate

A common armature plate is used, and during the change over from transmission to braking there is no interaction between the clutch and brake. Therefore heat generation and wear are minimised.

Maintenance

SG Transmission clutch brake modules are virtually maintenance free. However they are sometimes used to control large inertia loads with high switching frequencies and in these cases the air-gap between the clutch face and the armature plate should be regularly checked and adjusted if necessary.

Key features

- Simple fit to IEC motors and gearboxes

- Easy installation

- Zero-backlash

- Good heat dissipation

- High cycle times

- Voltage options

Product description

SG Transmission clutch brake modules are used whenever the prime mover is required to run continuously, and the output of the driving device requires a controlled “stop and start” action. This allows an electric motor to run while controlling its output via a clutch brake module. This will reduce the power consumption of the system considerably.

These modules are precision engineered with positive clutch and brake action with no backlash. They can be controlled by relatively simple solid state electronics to give accurate stopping and starting with frequencies over 300 cycles per minute.

Easy installation

The clutch and brake are ready assembled in a neat package which can be foot mounted or fitted to a standard IEC motor and reducer flanges.

Robust construction

Type 55 modules are completely enclosed and use deep groove ball bearings on the input and output. They can be mounted in any position, vertically or horizontally.

Zero backlash

The clutch and brake use a common driven armature, and therefore backlash during torque transmission and braking is eliminated.

Safety

Clutch and brake linings are hard wearing and do not contain asbestos.

Low wear rate

A common armature plate is used, and during the change over from transmission to braking there is no interaction between the clutch and brake. Therefore heat generation and wear are minimised.

Maintenance

SG Transmission clutch brake modules are virtually maintenance free. However they are sometimes used to control large inertia loads with high switching frequencies and in these cases the air-gap between the clutch face and the armature plate should be regularly checked and adjusted if necessary.

To download the technical drawings for this product fill in your details below and we will send you a link to the files.

"*" indicates required fields

See related downloads for full datasheet

| Size | Torque TS (Nm) | Max P20 (W) | A3 | B | C1 | C2 | C3 | D1 K6 | D2 H8 | E1 | H | P | R | S | S4 | T | V | X | Y | Z | Airgap (G) | Design no. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 06 | 8 | 13 | 102 | 177 191 | 85 | 100 | 71 | 11 14 | 44 | 9 | 63 | 72 | 94.5 | 23 30 | 38.5 45.5 | 4xM6 | 7 | 3 | 100 | 117 | 0.20 | 0601 |

| 08 | 16 | 21 | 128 | 209 229 | 110 | 115 | 105 | 14 19 | 50 | 10 | 71 | 90 | 107.5 | 30 40 | 47 57 | 4xM8 | 9 | 3 | 130 | 135 | 0.20 | 0801 |

| 10 | 32 | 31 | 153.8 | 254 274 | 142 | 135 | 128 | 19 24 | 62 | 12 | 90 | 112 | 120.4 | 40 50 | 49.5 69.5 | 4xM8 | 9 | 3 | 160 | 156 | 0.20 | 1001 |

| 12 | 65 | 34 | 193.5 | 301 321 | 160 | 155 | 150 | 24 28 | 74 | 14 | 100 | 137 | 136 | 50 60 | 73 83 | 4xM10 | 11 | 5 | 185 | 178 | 0.30 | 1201 |

| 16 | 120 | 45 | 250 | 351 391 | 195 | 170 | 169.6 | 28 38 | 100 | 16 | 132 | 130 | 168.5 | 60 80 | 90.5 110.5 | 6xM10 | 12.7 | 5 | 200 | 200 | 0.30 | 1601 |

| 20 | 240 | 65 | 268 | 395 435 | 235 | 185 | 225 | 28 38 | 120 | 16 | 158 | 215 | 177.5 | 60 80 | 106 126 | 6xM10 | 15 | 5 | 260 | 216 | 0.50 | 2001 |

See related downloads for full datasheet

| Size | Torque TS (Nm) | Max P20 (W) | A1 | B | D1 K6 | D3 H8 | D4 Max G7 | D6 +0.2 +0.3 | E2 | E3 | F1 | N | R | S | Ux4 | U4x4 | Airgap (G) | Design no. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 06 | 8 | 12 | 140 160 | 135 142 | 11 14 | 95 110 | 15 | 95 110 | 3 | 4 | 10 | 115 130 | 94.5 | 23 30 | 9 | M8 | 0.2 | 0608 |

| 08 | 16 | 21 | 160 200 | 157 167 | 14 19 | 110 130 | 24 | 110 130 | 3.5 | 4 | 10 | 130 165 | 107.5 | 30 40 | 9 11 | M8 M10 | 0.2 | 0808 |

| 10 | 32 | 31 | 200 | 88 198 | 19 24 | 130 | 28 | 130 | 3.5 | 4 | 12 | 165 | 120.4 | 40 50 | 11 | M10 | 0.2 | 1008 |

| 12 | 65 | 34 | 200 250 | 218 228 | 24 28 | 130 180 | 35 | 130 180 | 3.5 | 4.5 | 14 | 165 215 | 136 | 50 60 | 11 14 | M10 M12 | 0.3 | 1208 |

| 16 | 120 | 41 | 250 300 | 250 270 | 28 38 | 180 230 | 42 | 180 230 | 4 | 5 | 18 | 215 265 | 167.5 | 60 80 | 14 | M12 | 0.3 | 1608 |

| 20 | 240 | 58 | 250 300 | 287 307 | 28 38 | 180 230 | 50 | 180 230 | 4 | 5 | 18 | 215 265 | 177.5 | 60 80 | 14 | M12 | 0.5 | 2008 |